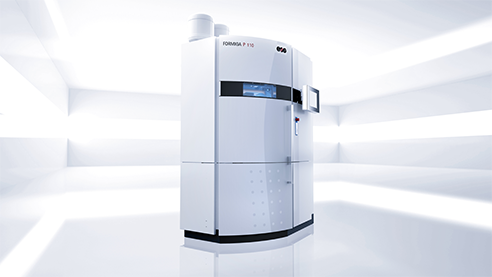

Compact laser sintering system for rapid prototyping applications and small series runs.

FORMIGA P 110 is a flexible, cost-efficient and highly productive system for the laser sintering of plastic parts. This compact system is ideal as an entry into laser sintering, for example for cost-efficient small series production, customised products with complex geometries and rapid prototyping applications. Without requiring tools, the laser sintering system makes direct use of digital CAD data to produce plastic parts of the highest surface quality to a maximum construction height of 330 mm.

Innovation

- Laser sintering of products directly from CAD data within just a few hours

- Cost-efficient, batch-size appropriate production

- Flexible balancing of component requirements (mechanical criteria, surface quality, consistency of form) with the greatest possible cost efficiency through the use of suitable EOS parameter sets

Quality

- Maximum reproducible part quality that has set quality standards in the market (“FORMIGA Quality”)

- Optimised thermal management (improved dosing tray tempering and new 4-channel heating)

Sustainability

- The material portfolio available for the FORMIGA P 110 encompasses materials with a high level of recyclability, thus reducing costs and protecting the environment

- During system development particular attention has been paid to low operating costs thanks to minimised energy consumption

- External connection to a central nitrogen supply reduces the amount of compressed air required by the machine

Efficiency

- Shortened cycle times thanks to the optimisation of the laser sintering process steps

- Minimum downtimes thanks to the streaming concept: the system can start building the job as soon as the job file is loaded

- Optimum usability of the construction space thanks to an improved thermal management system

Flexibility

- Easy integration in existing production environments

- A wide range of materials available (PA 2200, PA 2201, PA 3200 GF, PrimeCast 101, PA 2105 and other materials in planning)

- PA 2200 is now available in 0.06. 0.10 and 0.12 mm layer thickness

User Friendly

- Convenient handling through a high degree of automation and intuitive user interface

- Design for low-dust, ergonomic work conditions

- Data can be prepared in a convenient way in the workplace

FORMIGA P 110 |

|

|

Effective building volume |

200 mm x 250 mm x 330 mm |

|

Building speed (depending on material) |

up to 20 mm/h (0.79 in/h) |

|

Layer thickness (depending on material) |

0.06 mm, 0.1 mm, 0.12 mm (0.0024 in, 0.0039 in, 0.0047 in) |

|

Support structure |

not required |

|

Laser type |

CO2, 30 W |

|

Precision optics |

F-theta lens |

|

Scan speed during building |

up to 5 m/s (16.4 ft/s) |

|

Power supply |

16 A |

|

Power consumption |

2 kW |

|

Nitrogen generator incl. external nitrogen connection |

integrated |

|

Compressed air supply |

min. 6 000 hPa (87 psi); 10 m3/h (13.08 m3) |

Dimensions (W x D x H) |

|

|

System incl. powder containers and touch screen |

1 320 mm x 1 067 mm x 2 204 mm (51.97 in x 42.01 in x 86.77 in) |

|

Recommended installation space |

3.20 m x 3.50 m x 3.0 m (126 in x 137.8 in x 118.1 in) |

|

Weight |

approx. 600 kg (1.323 lb.) |

|

Unpacking and sieving station (optional) |

1 200 mm x 700 mm x 1 500 mm (47.24 in x 27.56 in x 59.06 in) |

|

Powder mixing station (optional) |

700 mm x 500 mm x 1,000 mm (27.56 in x 19.69 in x 39.37 in) |

Data preparation |

|

|

Software |

EOS RP Tools (optional); Desktop PSW |

|

CAD interface |

STL (optional: converter to all common formats) |

|

Network |

Ethernet |

Download

System Data Sheet FORMIGA P 110 | PDF