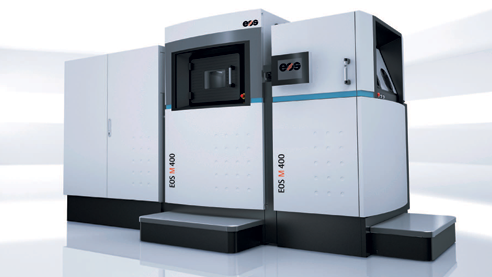

Leading-edge laser sintering system for the production of metal products directly from CAD data.

The EOSINT M 400 offers well-known and proven laser sintering quality for new metal applications. With a building volume of 400 x 400 x 400 mm, the M 400 allows the production of large metal parts on an industrial scale – directly from CAD data and with no need for tools.

A 1 kW laser boosts productivity due to higher build rates and increased layer thickness. Two recoater blades combined with bilateral recoating reduce the non-productive time of the system and ensure high-precision layer thickness. A recirculating filter system with automated cleaning reduces filter changes and extends filter lifetime, significantly reducing filter costs.

Modular Platform

- EOS M 400 consists of a Process Station and a Setup Station. This modular approach facilitates the easy integration of future innovations.

Enhanced Monitoring

- Extensive monitoring features take quality management to a new level.

- A camera integrated into the process chamber monitors the powder bed by taking single images — after recoating and after exposure.

- Parameters such as position of z axis, laser power, scanner position, humidity, temperature and pressure are monitored continuously.

Sophisticated Software

- Job preparation and calculation are separated from the building process: the job file prepared at your desk is transmitted via the network, while the system focusses entirely on building parts.

- This maximizes flexibility and efficiency for applicatio development, which can be done offline as the system remains free for building.

- This can be operated quickly and easily via a task-based layout on the touch screen.

- The fast offline job preparation feature enables users to quickly handle complex parts and large job files.

Improved Usability

- EOS M 400 supports the production of complex metal parts, yet the system is extremely user-friendly.

- Based on customer input, EOS and User Interface Design GmbH (UID) have developed an intuitive graphical user interface.

- This can be operated quickly and easily via a task-based layout on the touch screen.

- The wizard guidance supports the system operator.

Broad Material Portfolio

- EOS offers an increasing number of metal materials for the EOS M 400 system.

- With the corresponding ParameterSets, the system produces parts with standardized part property profiles (PPPs).

- The ParameterEditor enables you to modify parameters to meet your individual requirements.

Integrated Solutions

- Development of EOS systems, powder materials, process parameters, software and services go hand in hand. All elements are optimally aligned. The result: high-quality and cost-effective production of parts with first-class properties for their dedicated application.

EOSINT M 400 |

|

|

Building volume |

400 mm x 400 mm x 400* mm (15.8 x 15.8 x 15.8 in) |

|

Laser type |

Yb-fibre laser; 1 kW |

|

Precision optics |

F-theta-lens |

|

Scan speed during build process |

up to 7.0 m/s (23 ft/s) |

|

Focus diameter |

approx. 90 μm (0.0035 in) |

|

Power supply |

50 A |

|

Power consumption |

max. 20.2 kW / typical 16.2 kW |

|

Nitrogen generator |

integrated |

|

Compressed air supply |

7 000 hPa; 20 m3/h (102 psi; 706 ft3/h) |

Dimensions(W x D x H; Process Station (with Periphery Station) and Setup Station) |

|

|

System |

4,181 mm x 1,613 mm x 2,355 mm (164.6 x 63.5 x 92.7 in) |

|

Recommended installation space |

minimum 6.5 m x 6 m x 3.3 m (256 x 236 x 130 in) |

|

Weight |

approx. 3,240 kg (7,143 lb) |

Data preparation |

|

|

Software |

EOS RP Tools; EOSTATE; EOSPRINT; Materialise Magics RP with SG+ and further modules |

|

CAD interface |

STL, optional: converter for all standard formats |

|

Network |

Ethernet |