EOS Laser Sintering Software Solutions

EOS has released its latest software solutions for laser sintering production. Scalable and automated production, and seamless integration into existing production environments, can be challenging. EOS offers software to help companies achieve the next level of industrial 3D printing.

“The goal is to integrate AM technology wisely and efficiently into existing and future production lines. Customers face topics such as quality of parts, quality control, scalability, automation and total cost of ownership. We address these challenges to ensure that companies can put industrial 3D printing to successful use.”

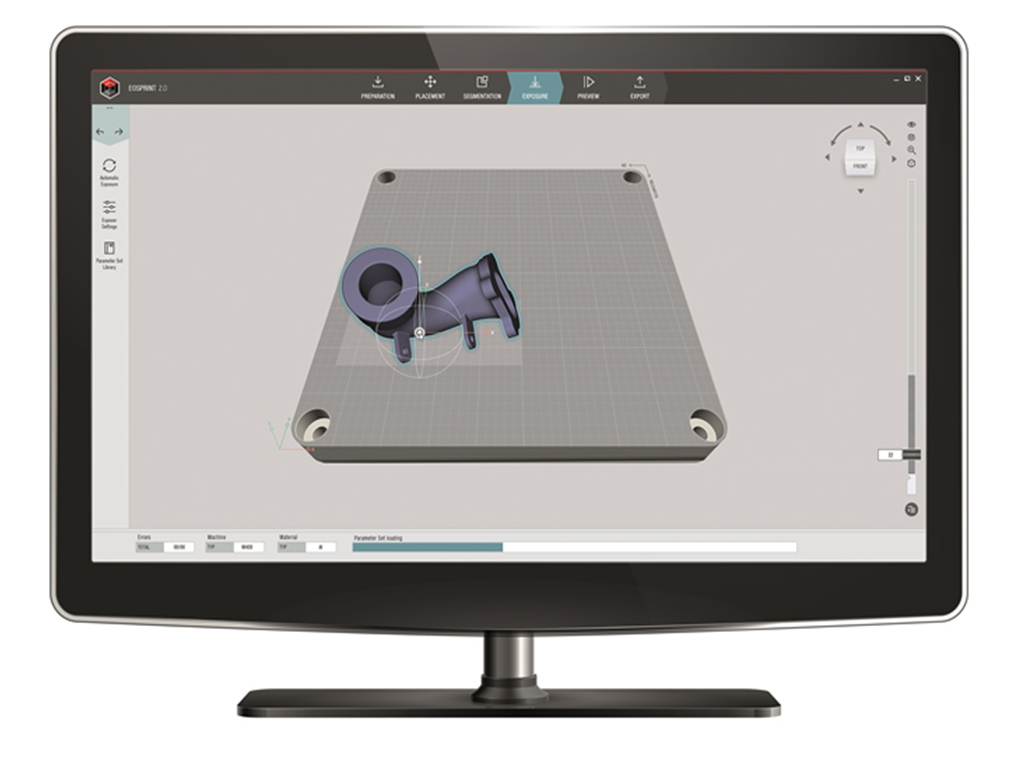

EOSPRINT 2.0: faster and more reliably from the idea to the product in series production

With EOSPRINT 2.0, EOS offers a comprehensive AM CAM environment for engineers to fully leverage the benefits of laser sintering with production-ready design. EOS has integrated numerous improvements and addressed customer requirements, particularly in the field of operability. This makes the initial steps of the build process easier. Users increase their productivity in construction while experienced developers profit from the new ParameterEditor (PE) module as part of EOSPRINT. Intuitive in its handling and with a large tool set, the PE module offers greater freedom for application-specific parameter optimisation and helps improve the part quality.

EOS cooperates with Siemens and Autodesk on EOSPRINT to further improve the user experience:

- With EOSPRINT for Siemens NX™ users can integrate EOS CAM software in the CAD tool Siemens NX™ allowing designers to work continuously in one familiar software environment. With this integration, users get an efficient environment to experience and optimise their product ideas before starting the laser sintering build process.

- ]Users of Autodesk Netfabb 2017 can now select EOS systems for data preparation in the Workspace Manager and send build jobs directly via the EOS OpenJob Interface of EOSPRINT. What’s more, for metal build process simulations Netfabb users can select and use the matching values for EOS materials directly.

These measures enable companies to manufacture additively in series faster and more reliably with EOSPRINT.

EOSTATE Monitoring Suite: quality assurance thanks to holistic monitoring solutions

EOS extends its EOSTATE Monitoring Suite for quality assurance and process development in metal 3D printing with EOSTATE Exposure. This solution analyses the melting and cooling behaviour of the complete melt pool. Indicators provide automatic feedback on possible sources of errors for evaluation. In this way, companies can draw conclusions about the quality of the part built and ensure a traceable and constantly high quality of parts.