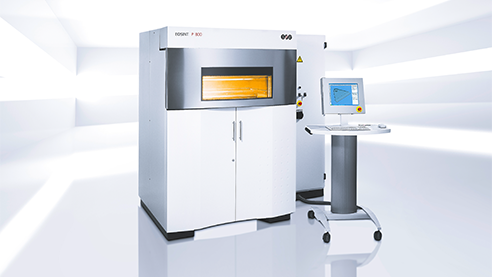

Highly productive, modular laser sintering system for the production of high-performance plastic components.

EOSINT P 800 is the world’s first laser sintering system for the production of high-performance plastic products at required high process temperatures. The system uses a layering process on high-melt polymers at temperatures of up to 385 °C, producing parts with remarkable properties. During the production process, the integrated online laser power control module continuously monitors laser performance ensuring optimum, reproducible results.

Innovation

- The world’s first laser sintering system for the production of high-performance plastic products

- The system is designed for high-performance polymers and the adapted process with process temperatures of up to

385 °C fully exploit the possibilities of thermoplastics with laser sintering production

Quality

- The best possible use of the property profile of high-performance polymers

- The continuous monitoring of laser performance by the online laser power control module drastically reduces possible

variations in quality

Sustainability

- The partly deficient heat dissipation is responsible for long cooling periods for the manufactured products. Components produced from these materials can perform just as well as metal materials but weigh far less

- The energy-intensive process was made much more cost-effective through the use of efficient machine insulation

Efficiency

- The shortest possible throughput times thanks to optimised processes

- The heavily insulated machine enables the high-temperature EOS PEEK HP3 material to be processed in an energy-efficient way

Flexibility

- Easy integration in existing production environments

- Modular, upgradeable EOSINT system

User Friendly

- Convenient handling thanks to a high level of automation

- Low-dust, ergonomically efficient working conditions

- Blade cartridge concept makes for easy adjustment and uncomplicated changes of layer thickness

EOSINT P800 |

|

|

Effective building volume |

700 mm x 380 mm x 560 mm (27.6 x 15 x 22.05 in) |

|

Building speed (depending on material) |

7 mm/h (0.3 in/h) |

|

Layer thickness (depending on material) |

typically 0.12 mm (0.005 in) |

|

Support structure |

not required |

|

Laser type |

CO2, 2 x 50 W |

|

Precision optics |

F-theta lens |

|

Scan speed during building |

up to 2 x 6 m/s (19.7 ft/s) |

|

Power supply |

32 A |

|

Power consumption |

maximum 12 kW / typical 3.7 kW |

|

Nitrogen generator |

integrated |

|

Compressed air supply |

minimum 20 m3/h; 6,000 hPa (26.2 yd3/h; 87 psi) |

Dimensions (W x D x H) |

|

|

System incl. switching cabinet |

2,250 mm x 1,550 mm x 2,100 mm (88.6 x 61 x 82.7 in) |

|

Control terminal |

1,045 mm x 850 mm x 1,620 mm (41.1 x 33.5 x 63.8 in) |

|

Powder conveying system |

1,890 mm x 1,350 mm x 1,550 mm (74.4 x 53.2 x 61 in) |

|

Unpacking station |

1,600 mm x 800 mm x 1,370 mm (63 x 32 x 53.9 in) |

|

Recommended installation space |

4.8 m x 4.8 m x 3.0 m (189 x 189 x 118 in) |

|

Weight |

approx. 2.300 kg (5,071 lb) |

Data preparation |

|

|

PC |

current Windows operating system |

|

Software |

EOS RP Tools; EOSTATE; Magics RP (Materialise) |

|

CAD interface |

STL (optional: converter to all common formats) |

|

Network |

Ethernet |

|

Certification |

CE, NFPA |

Download

System Data Sheet EOSINT P800 | PDF